|

Characteristics of Taiwan Melamine tableware |

-

Manufactured in a JIS authorized factory under strict qualify control.

Taiwan Melamineˇ¦s products are manufactured in a factory with shaping

materials qualified JIS spec (JIS-K-6917-1977). The factory has been certified since year 1966 with certificate JIS ˇVS-2029-1984 (Certificate No. 366218). -

All products are compatible with Sanitary Standard.

Taiwan Melamineˇ¦s products are following the sanitary standard of regulations and laws. -

Taiwan Melamine has been executing strict test of industrial self-regulations and spec in order to provide safe products to customers.

-

Taiwan Melamine is the first company applying practical collage shaping method in Taiwan.

The

paper/tinsel collage shaping method

was developed in Switzerland. Taiwan

Melamine was the first one to import

the technology into Taiwan and

successfully applied to the

products. The characteristics of

paper/tinsel are as below:

1.Colorful chromophore

2. Unity with finish goods with low

peel-off rate

3. Nearly no color rendering.

(Paper/tinsel means the one that has

printed patterns on a Japanese

paper, be immersed in Melamine Resin

and dried.)

-

Pre-heating for even hardening

Pre-heat the materials before shaping. The finished products are with even hardening and high stability. -

High-pressure shaping

Use high-pressure as 200kg/1 cm2 in a large shaping machine. The even hardening of surface leads to low scratch and broken rate. -

Use special ink for pattern printing

Compared to other ink, the special ink could immerse in paper/tinsel with low peel-off rate and discoloration rate of patterns. The special materials could be filtered before shaping with the printing side inside. -

Use GLAZE spread-plate method

Taiwan Melamine use glaze spread-plate method on surface of products in order to increase the stability and undefilement of the surface. -

Decrease sharp points

The sharp points have been decreased in order to decrease defilement and broken rate. -

Heating for better stability

Heat for one hour when the temperature reaches 130˚ C after shaping, strengthen and stabilize the combination of molecules in order to increase stability. -

Provide special design for collection and piling.

-

Thermosetting Hardened Resin

The resin owns the highest hardness on surface with low rate of scratch or defilement. -

The specific gravity is about 1.5 with proper weight perception.

-

Great heat preservation with low heat transfer rate

-

The heat transfer rate of the material is low. The product could be easily held with hot foods inside.

Notes

-

Please do not use the product in microwave or oven.

-

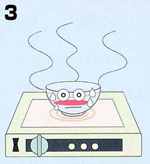

Please do not roast directly on the fire or approach fire

-

Please do not hit the product or use it under dramatic change of temperature in order to decrease broken rate.

-

Please do not hit the product strongly in order to decrease broken or scratch rate.

-

Please do not use any products with broken edge.

-

Please do not use any product as an ash tray other than an ash tray.

-

Please do not fire in an ash tray or ash bin.

-

Please do not put the product inside a hot iron plate or hot pot for heat preservation.

|

ˇ@ |

|

| Please do not use the product in microwave or oven. | ˇ@ | Please do not roast directly on the fire or approach fire |

|

ˇ@ |

|

| Please do not put the product inside a hot iron plate or hot pot for heat preservation. | ˇ@ | Please do not fill in hot oil or chemical. |

Cleansing

-

Do not use scrub or brush in order to prevent scratch.

-

Please rinse thoroughly after cleansing and bleaching.

-

Please do not use bleaches containing Chloride in order to prevent material deterioration or color change.

-

Please do not use beaches containing Chloride to clean defilement which is not being cleaned with detergent.

-

The surface (pattern) of product may be damaged when immersed in hot water for a long time. Please immerse the product in warm water between 30~40˚C for 15~20 minutes if necessary.

Disinfection and Storage

-

Please use heat air storage room and set the indoor temperature as 80~85˚C. After reaching the degree for 20~30 minutes, please note the extremely high temperature at the outlet of heat air.

-

Disinfection by boiling may cause deterioration of the finished products. Please shorten the time for boiling to the minimum timeframe and avoid boiling for a long time.

-

Please use oxygen bleach instead of Chloride bleach when bleaching. Using Chloride bleach will cause the tableware be out of brightness, with loose handle, and the color will became yellow. Please note the quantity of bleach and fully rinse with water.

ˇ@